The clean room is defined as "a room designed to control suspended particles below the designated value as well as the temperature, humidity, pressure, and airflow". Its effect greatly depends on the air flow direction, the room construction and ventilation times. Specifications must be determined based on the type of operation and cleanliness of the product so that the air flow will not be turbulent and dust will not be accumulated. There are 3 types; Down (vertical) flow type, Cross (horizontal) flow type, and Conventional (turbulent flow) type. Also, there are 3 installation methods; construction, prefabrication and unit. Each should be selected depending on the required cleanliness, operation, facility cost, etc....

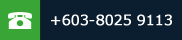

Designed to provide a high velocity air wash of personnel to remove surface particles before entering a controlled Clean Room environment. It can also serve as an air lock.

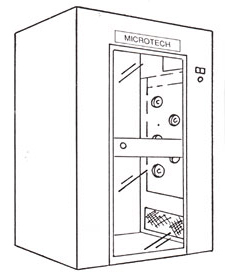

Microtech MTT series laminar flow work stations create an ultra clean area for operation requiring particle-free environment. Most aseptic procedures may be performed safely in this equipment.

This is used to maintain the inside pressure of a clean room.

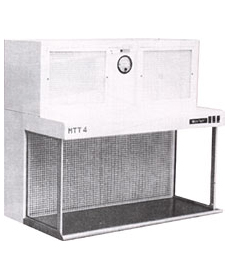

Pass-thru boxes are used to minimize introduction of contaminants and human traffic into the clean room.